Our Story

I became involved in grass skiing in 1995 as a convenient alternative to alpine skiing. This was due to limited availability of snow on glaciers and opportunities for gate training. Gradually, grass skiing became my primary sport because of the extensive training possibilities near my home.

The idea of producing parts and eventually entire grass skis emerged from the challenges we encountered when ordering racing skis. These required orders to be placed six months ahead of time, and often the skis had to be disassembled, modified, polished, and reassembled. Acquiring spare parts promptly was also difficult when something broke or cracked. My father started producing new parts, which caught other racers' attention, leading us to expand our production.

In 1999, we began using skis from Austrian manufacturer Balek, which allowed us to source skis and parts more reliably, albeit at a higher cost. We started making parts for Czech skis similar to those for Austrian ones and added more components to our production over time.

Since 2018, I have retired from active racing to concentrate on my children. My son Matyáš began grass skiing at age 8, and his performance the following winter confirmed the positive impact of summer training on his winter results.

Our production facilities

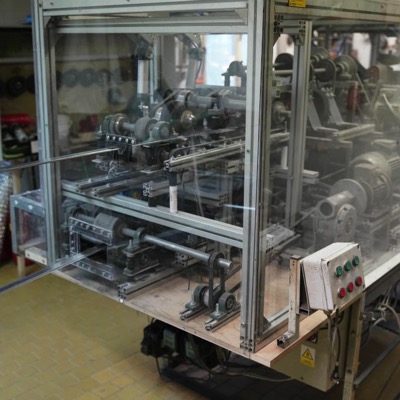

We are constantly striving to improve and innovate our production process and machinery, and despite being a small-scale, manual production, we are incorporating modern elements and computer control to achieve the best quality and features.

Our machinery includes larger machines such as:

- Arburg ALLROUNDER 221 M 350-75 Injection Molding Machine

- CNC lathe Mazak QT-6 with Hydrafeed bar feeder

- 1500W fiber laser welding machine

- CNC hobby milling machine - 3 axes

- 2x CO2 laser

- 1x marking FiberLaser

- 2x CNC profile bending machine

- Mechanical 20t Press

- bottom wood cutter

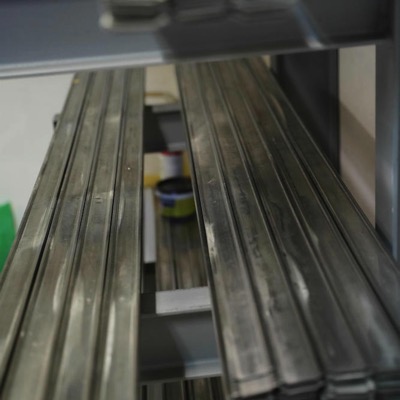

- computer controlled profile grinding machine

We source parts and components from local suppliers and manufacturers, such as profile profiles, plastics, and textile straps. However, we produce and process everything ourselves to ensure production control and flexibility in innovation.

Basic facts

1997

Production of first rolls for ski named Šojat

1997

1998

First TiN surface coating on rails

1999

Laser made holes in belts

1999

1999

Production of parts for Balek grasski

2001

Our cooperation with producer Balek began

2001

2007

Design of new element for Balek

2011

Production of our own element

2011

2013

Purchase of own laser for cutting holes in belts

2014

Production of own rails

2014

2017

Production of element v2

2017

Purchase of Fiber Laser

2017

2017

CNC Lathe Mazak

2018

Computer control grinding machine

2018

2019

Arburg Injection molding machine

2019

Production of element v3

2019

2022

Four new molds

2023

Laser welding

2023